Parameter configuration of WRD5181THX series MMA cold plastic (cold paint) road marking truck

Cost-effective

High degree of integration.

The working devices are arranged on the left and right sides, equipped with four marking operation devices of MMA cold plastic spraying, screeding (vibration), dot line type and structural line type, which can be switched to the best working device according to the needs of the project.

Integrating the three functions of transportation, melting and marking, it is equipped with paint tanks and glass bead tanks with uninterrupted and recyclable feeding, which can meet the construction needs of long-distance, uninterrupted, and large-scale marking projects. In addition, it is fully intelligently controlled and does not require ground-assisted staff. There is little on-site preparation work, the construction is completed quickly, and the transition is quick and convenient, safe and reliable.

High work efficiency

Two 1500L large-capacity barrels provide a strong guarantee for continuous construction operations, which greatly shortens the construction period and reduces construction equipment configuration; two 750L large-capacity pressure glass bead tanks are equipped with an air drying system in the tank and uninterrupted circulating material supply system and the sealing and fixing system of the feeding port completely avoid the disadvantages of the glass beads being wetted by the gambling gun, the glass beads are broken during the construction, and the pressure is slow or the pressure leaks. The patented glass bead spray gun that can adjust the pressure and flow of glass beads can fully meet the requirements of glass bead spraying for different marking types.

High configuration

Equipped with a fully imported hydraulic transfer (hydraulic drive) system with stable performance, convenient operation and free control. The traveling speed of the vehicle can be adjusted arbitrarily according to the construction needs, and the traveling speed can be realized at a constant speed according to the selected traveling speed, ensuring uniform thickness of marking lines, uniform intervals, and neat lines.

The configured microelectronic control system meets the basic functions of precise control, digital line input, remote control operation and other basic functions according to the line standard and construction requirements. At the same time, it can also be equipped with an automatic line data collection and analysis system according to user needs. In order to easily realize the automatic collection, calculation and printing of construction parameters within unit time such as paint consumption, marking length, construction area, etc., as well as automatic evaluation, warning and printing of construction conditions such as construction quality (thickness prompts, etc.) and real-time positioning;

Equipped with high-brightness LED guide warning screen, can effectively improve the safety of marking operations. The multi-position adjustable seats that meet the ergonomic requirements can significantly improve the comfort of marking construction.

With modular design on the same platform, users can choose between various MMA cold plastic road marking systems such as MMA cold plastic screeding (vibration), spraying, structural line type, and extrusion line type by replacing paint tanks and working devices.

Accurate operation

It can adjust parameters such as operating device, vehicle walking speed, glass bead spraying speed and other parameters according to construction needs. It can realize fixed width, fixed speed and uniform speed according to the selected walking speed to ensure that the marking line is neat and beautiful, uniform in thickness, and consistent in spacing, high reflectivity.

It satisfies the functions of precise control, digital linear input, and remote control operation for users in accordance with linear standards and construction requirements. The whole machine adopts a modular design, and can be customized according to customer requirements and adapted working devices to ensure that users can choose different marking systems according to the different marking types they are constructing.

Features of products

This series of marking trucks adopts the same platform modular design, users can choose different marking systems or integrate multiple marking systems according to their own needs. The whole truck adopts high-grade electrophoretic coating or compound electroplating treatment, which has excellent anti-corrosion and anti-rust performance. The whole system comes standard with a fully imported hydraulic transfer system, an intelligent marking control system and an uninterrupted circulating feeding system. The specific system configuration:

(1) A variety of construction methods can be integrated: users can choose one or a combination of multiple marking construction methods according to their own needs, and the combined module adopts a convenient way of disassembly and assembly, which is convenient for switching the construction system. Optional construction system:

MMA cold plastic (cold paint) airless spraying system (CPAL): dual-match imported brand alloy piston pumps, single pump flow 20L/min, wear resistance, large flow, stable pressure, spraying pressure can be adjusted in the range of 0-25Mpa to meet the needs of users for different paint types, different marking thicknesses and widths. The perfect combination of variable pump and automatic reciprocating hydraulic cylinder, and eliminates the complicated electronic control system,which can provide continuous, long-lasting and stable driving force for the paint pump.

MMA cold plastic screeding system (CPSC): MMA cold plastic screeding system with unique structure design ensures uniform marking thickness and neat head and tail. In addition to the function of marking ordinary flat lines, it also can mark vibration line include square and rib line markings. Built-in hydraulic (or electric) driven butterfly mixing blade, large torque, uniform and powerful mixing, reliable operation, to ensure uniform mixing of paint and curing agent. The movable parts of the paint hopper are designed with a snap-in design, which is more convenient and quick to disassemble, clean and maintain.

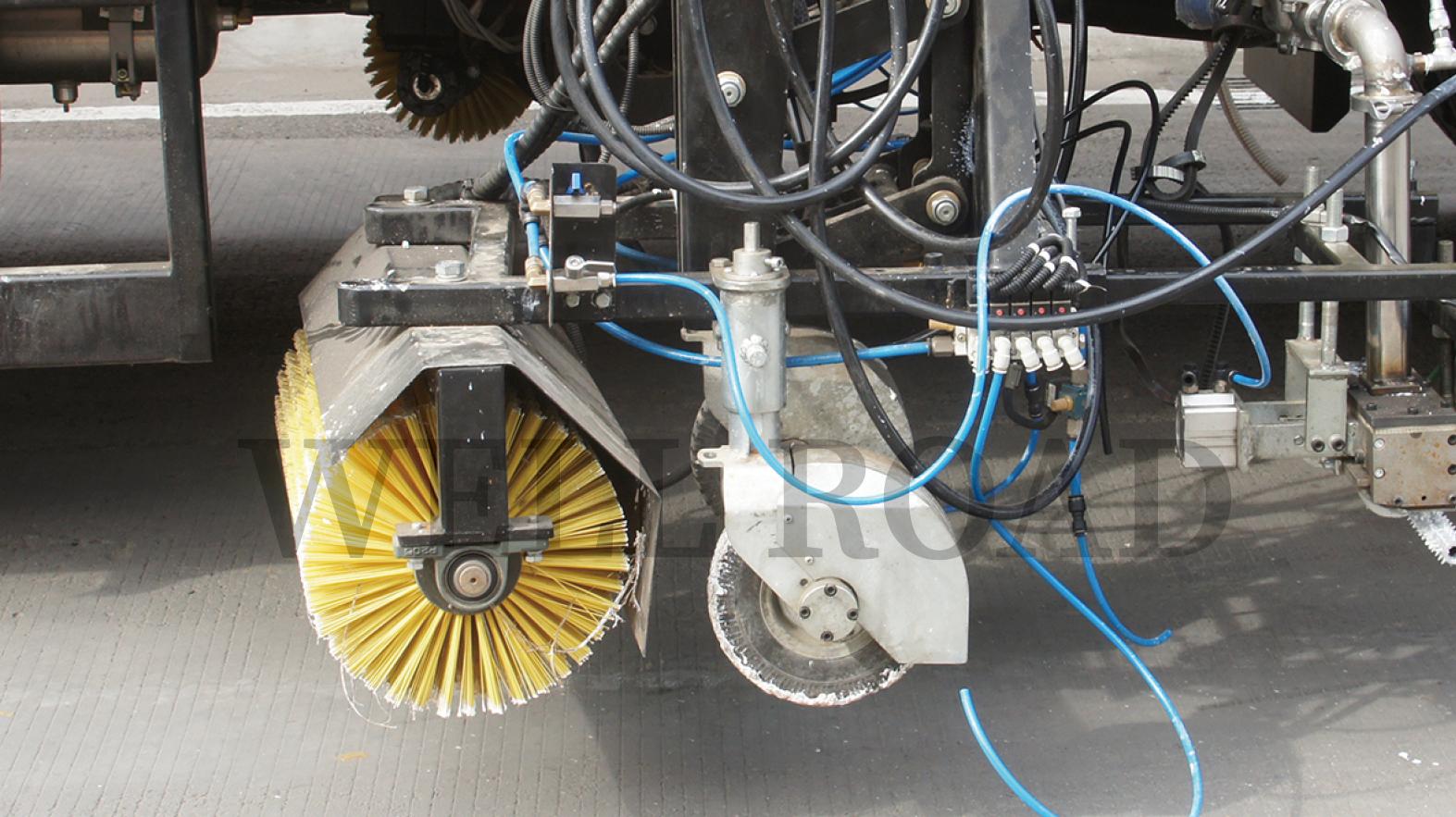

MMA cold plastic structural line system (CPTH): Equipped with a centrifugal spin paint system that is easy to disassemble and assemble. The centrifugal speed and paint flow can be adjusted in real time according to construction needs. By replacing hoppers of different widths, the construction needs of different width markings can be met.

MMA cold plastic extrusion system (CPEX): Equipped with a multi-layer combined extrusion cavity that is convenient for disassembly and maintenance, and a linear grouped closed air passage design, which not only reduces the volume of the extrusion cavity, but also realizes line types are switched smoothly, so that the dotted line is neat and tidy, and avoids the phenomenon of dots adhesion. Built-in dynamic and static mixer to ensure uniform mixing of paint and curing agent.

(2) Equipped with a fully imported hydraulic transfer system: to achieve precise control of the construction speed, and freely switch between low and uniform speeds to ensure the quality of the marking. The large-capacity hydraulic oil tank equipped with a new cooling system can ensure that the hydraulic system can always maintain a relatively stable cooling value during continuous operation, and effectively improve the operating life of the hydraulic system.

(3) Intelligent marking control system: While satisfying users' basic functions such as precise control and line selection input in accordance with line type standards and construction requirements, the automatic collection and analysis system of construction marking data can be added according to user needs. In order to easily realize the automatic collection, calculation and printing of construction parameters within unit time such as paint consumption, marking length, construction area, etc., as well as automatic evaluation, warning and printing of construction conditions such as construction quality (thickness prompts, etc.) and real-time positioning;

(4) Uninterrupted circulating feeding system: sealed (or pressurized) type large-capacity paint tank and glass beads tank, which can not only meet the construction needs of large-scale, long-distance, uninterrupted marking engineering, but also completely avoid paint prolonged contact with air may affect physical and chemical indicators such as paint viscosity or the occurrence of moisture on glass beads. A warning can be issued when the amount of marking materials is insufficient to avoid supply interruption during the construction process.

(5) Precise paint and curing agent mixing control system: Using microcomputer precise control, curing agent delivery volume and paint delivery volume are precisely controlled by setting parameters to ensure accurate paint and curing agent ratio. Equipped with a quick cleaning system to facilitate the rapid cleaning of the marking system during construction, facilitate equipment maintenance and improve use efficiency.

400-600-5128

400-600-5128